In numerous fields of application, electronic components and assemblies must be specially sealed in order to be protected against the effects of water, condensate, dust or dirt. A special challenge for the sealing process of printed circuit boards is their assembly with electromechanical components such as tactile switches. In the following, we present the three most common processes, conformal coating,potting and dip coating.

In conformal coating, a distinction is made between dip coating and selective coating with a spray head. With selective coating, only critical components and contacts can be coated, thus saving costs by using less material. Coating protects against condensation or contamination and also provides ESD protection. In the case of MICON and RACON, the flexible pressure piece should be left out during coating, as otherwise coating particles can flake off when the button is subsequently actuated.

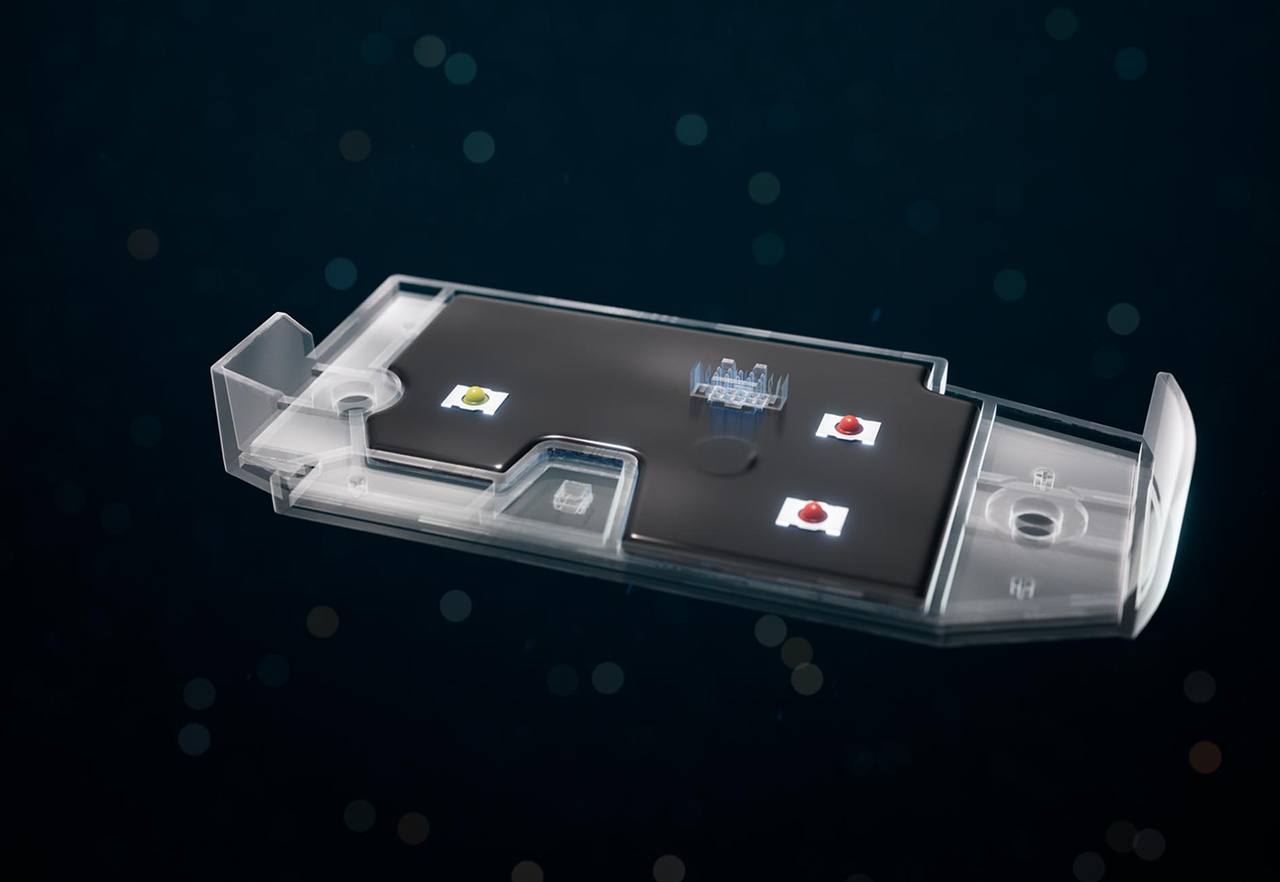

In potting, the printed circuit board is partially or completely filled with a medium which offers not only excellent protection in constant humidity but also mechanical protection in case of vibration and improved heat dissipation. This can significantly extend the lifetime of the electronics. The new generation MICONs and RACONs (sealed) can now be effectively enclosed up to the defined potting height and continue to function reliably thereafter.

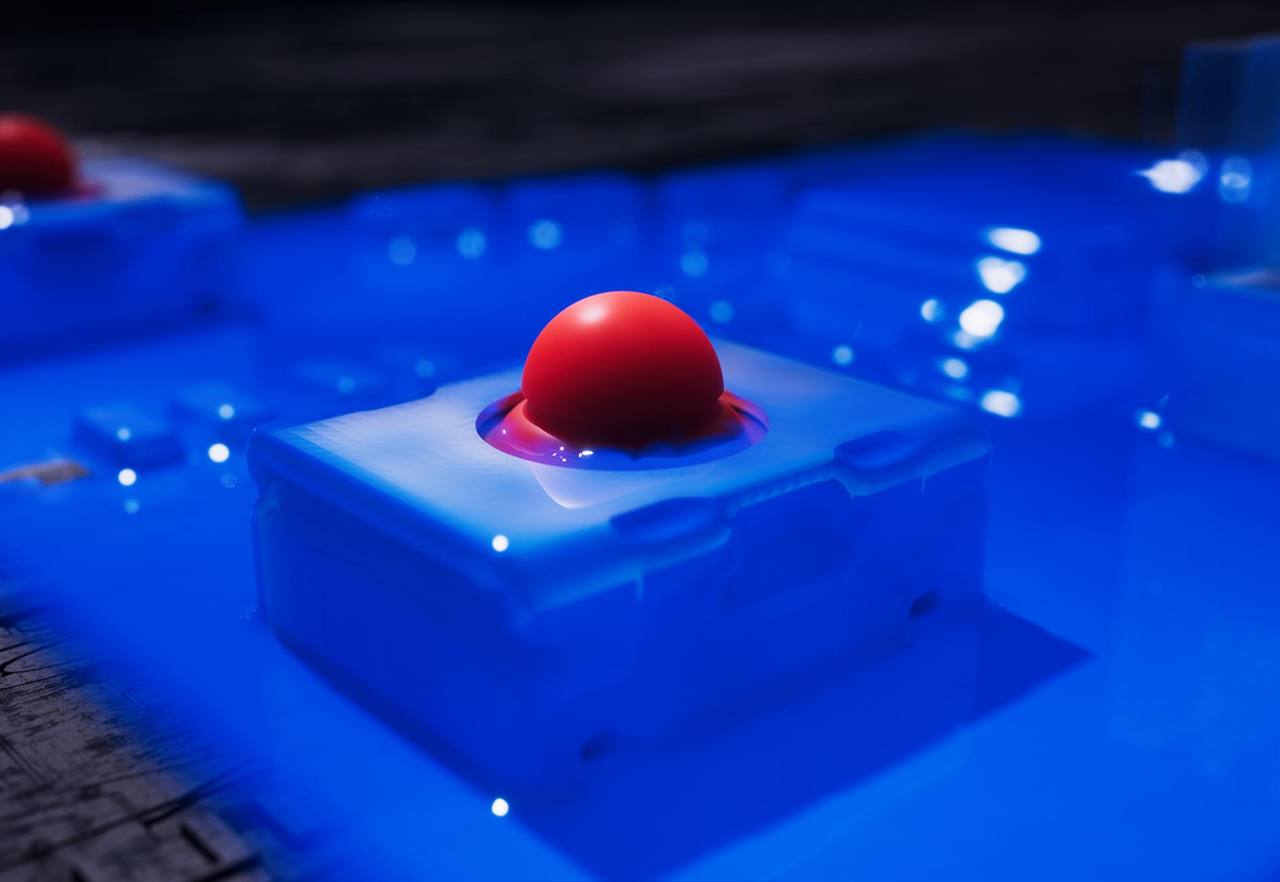

Dip coating is usually applied in an immersion process in which the assembled circuit board is immersed in a basin. The coating material penetrates into every corner of the assembly in order to provide the best possible protection for the circuit board. A thin layer of just 400 nm is sufficient to reliably protect the electronics from malfunctions and moisture. However, using this type of coating on tactile switches is a challenge – but MICON as well as RACON are ideally suited for exactly this purpose.

Product video